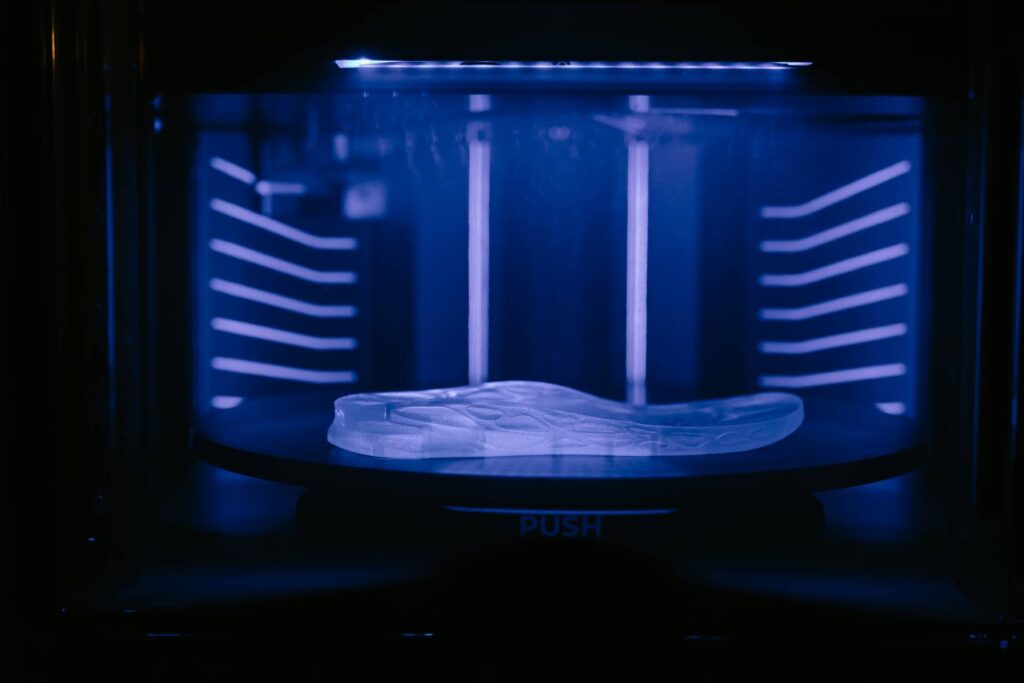

Frasson is equipped with a latest generation 3D printer, used for the prototyping phase.

3D modelling is a powerful tool for footwear design and production. Prototyping with soft mockup offers increased speed, accuracy and visualization capabilities for every custom-made project.

The film was developed to permanently glue together the various layers which make up the sole and wedge of a shoes. Depending on the construction of the various components and on the material used, the film can be applied before or after the molding phase. A 100% EcoBond sole avoids the production of large amount of powder, greatly reduces the use of glue and reduces solvent emissions into the atmosphere.

Hyperlink is an innovative assembly system that make up a sole for footwear with a rubber tread. The innovative film that covers the wedge acts as a binding vehicle between a specially designed rubber and the polyurethane wedge or other technical components (heels / shank / aesthetic details / label and much more). With Hyperlink, the benefits of rubber as a technical and noble material of a tread are combined with the flexibility of TPU as a classic over-injection system used in the world of footwear.

A construction that combines the physical-mechanical characteristics of EVA- shock absorbing and lightness- with the advantages of PU- rebound and compression set, as well as high resistance and durability. This technology can also be combined with EcoBond and SpeedProcess smart assembly systems.

This structural technology was developed and patented to reduce the weight of rubber soles by up to 20% thanks to its special structure and an innovative gluing system that guarantees durability and performance at the midsole.

The new concept of multi-compound solewas inspired by the world of competitive tires, where each rubber compound must accommodate the specific demands of each driver and track. At the same time, a rubber sole must be assembled using different compounds that satisfy specific performance needs determined by its area of use.

A special thermoplastic skin protects the PU midsole from bacterial and hydrolysis attacks, defending the structure from hits and tears. In additional to this, the film technology guarantees a great opportunity to develop new designs for the midsoles.

P.IVA 03397900261